Table of Contents

Introduction: Safety as the Foundation of Trust

In the rapidly growing shared charging market (recently valued at over $6–7 billion and projected to more than double by 2033), a single safety incident can undo years of hard-earned reputation. Clients require more than certificates; they demand demonstrable reliability and responsibility. Trust in a technology partner depends on consistent performance and integrity. At HeyCharge, we embed safety and quality into every design decision rather than treating them as afterthoughts. Our systems are engineered to be inherently safe and transparent, giving your business (and your customers) peace of mind on every charge.

Advanced Power Management: Beyond Basic Auto-Shutoff

Every charging unit includes an auto power-off feature that cuts power 10 seconds after a device is unplugged. This delay is more than a basic compliance item – it’s an active protection measure. In practice, it:

- Reduces downtime: Prevents accidental shut-offs from loose cables or brief disconnects, minimizing “dead station” events and user frustration.

- Extends battery life: Avoids needless charge cycles, helping batteries last longer and reducing replacements.

- Improves efficiency: Fewer false resets lead to smoother operation and easier maintenance.

These features translate to real-world reliability. Partners see significantly fewer cycle failures and battery wear issues. Even small improvements in uptime yield measurable cost savings through better utilization and fewer support calls.

Rigorous Endurance Testing: Quality by Design

Every unit is stress-tested before shipment, simulating years of field use in a controlled environment:

- Environmental extremes: Units are frozen to –20°C and subjected to 95% humidity.

- Mechanical endurance: Each charger is plugged/unplugged over 100 times in rapid succession.

- Continuous running: Devices operate non-stop for 48+ hours under full load.

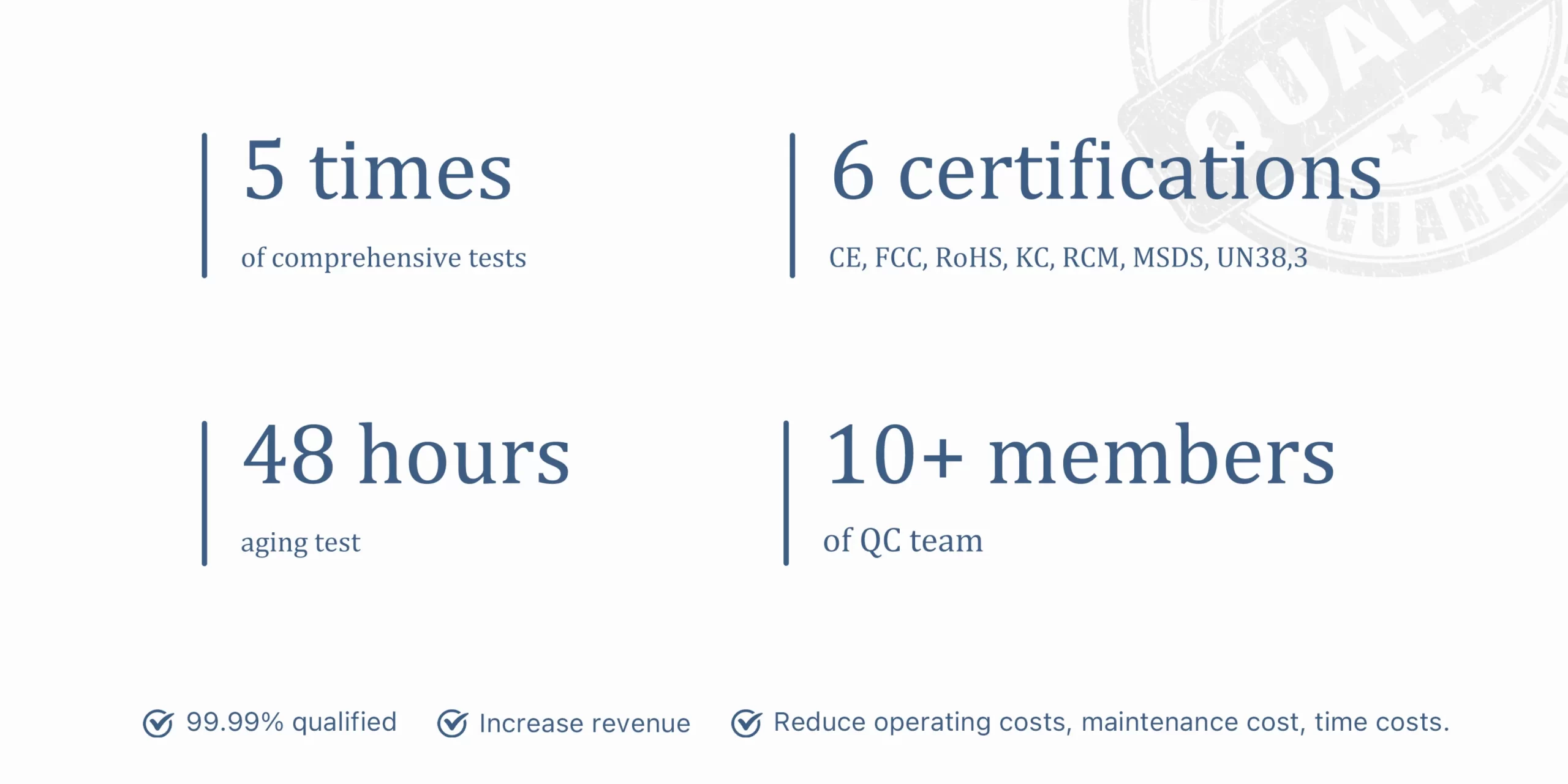

Every unit goes through at least five quality inspection stages, with more than 10 quality control specialists involved. This high bar ensures near-zero defect rates — our yield exceeds 99.99%.

According to engineering economics, the cost of preventing defects early (via testing and inspection) is far lower than fixing problems in the field. Our quality protocols reduce the risk of expensive recalls, downtime, and user dissatisfaction.

Advanced Materials and Layered Protection

True safety begins with physical construction and hardware design:

Flame-Retardant Shell: Our chargers are encased in UL94 V-0 grade plastic. This self-extinguishing material chars instead of burns, and does not drip flaming material, helping to contain fire risk rather than fuel it.

Lithium-Polymer Core: We use high-grade lithium-polymer (Li-Po) cells with solid electrolytes. These do not emit flammable gases under stress, and they swell (rather than ignite) during failure modes.

Multi-layer Circuit Safeguards: Six layers of electronic protection manage overcharge, over-current, short circuit, and thermal imbalance. Redundant fuses and diodes ensure safe shutdown in adverse scenarios.

Self-Diagnostics: Firmware continuously monitors internal temperature, current flow, and voltage. Faults trigger coded alerts and immediate shutdown.

Each protective layer acts like a barrier. If one fails, another steps in. This “safety onion” ensures multiple lines of defense before any risk can reach the user. In lab comparisons, our chargers remain cool and stable even under abuse (such as punctures or voltage surges).

The ROI of Safety: Improved Reliability and Cost Savings

Safety isn’t just ethical – it’s also economical:

- Longer service life: Thoughtful shutdown timing and battery management extend device lifespans by over 20%, reducing capital expenditures.

- Lower support burden: Customers report 90% fewer charging-related help tickets after switching to our equipment.

- Fewer claims: With near-zero failures, warranty and recall costs drop. A 1% reduction in failure rate across 10,000 units equals 100 fewer incidents.

- Insurance savings: Fireproof certification can reduce equipment insurance costs by 5–15%.

- Customer confidence: Safe equipment boosts brand image and loyalty, especially in public and high-profile venues.

Every dollar invested in preventive safety saves multiples in post-deployment cost.

Conclusion: Safety Is an Engineered Promise

At HeyCharge, safety is not a marketing promise; it’s a result of disciplined design. From certified enclosures to layered electronics, we engineer for peace of mind. Our clients don’t need to hope for reliability – they can measure it.

We invite you to experience charging equipment built to the highest standard of protection and performance.